High-grade 92% and 95% alumina abrasion-resistant ceramic lining

Slurries, sand particles, and corrosion can all eat away at the structural integrity of metal parts, leading to their gradual destruction. But they can be adequately protected from such substantial damage and thus save you from downtime-related woes. Fine-grain 92-95% Al2O3 abrasion-resistant ceramic products from Chemshun Ceramics can act as a barrier between your metal surfaces and abrasive materials. They are proven to add to the efficiency of your equipment by preventing it from getting out of service due to excessive wear and tear.

Thanks to their protective properties, our ceramic abrasion-resistant lining have already found their way in many industrial applications. They can be used to complement the structural strength of coal feeders, grinders, conveyor systems, ball mills, hoppers, pipes, chute, and more. By helping these components remain up and running as long as possible, our products ensure a sense of reliability in your manufacturing procedures. No matter whether you’re operating in the mining, coal, or steel industry, these ceramic lining are your best fit to withstand the impacts of heavy-duty usage.

Special features behind our abrasion-resistant ceramics

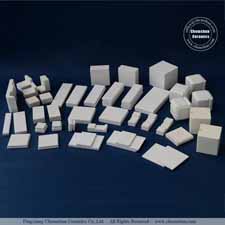

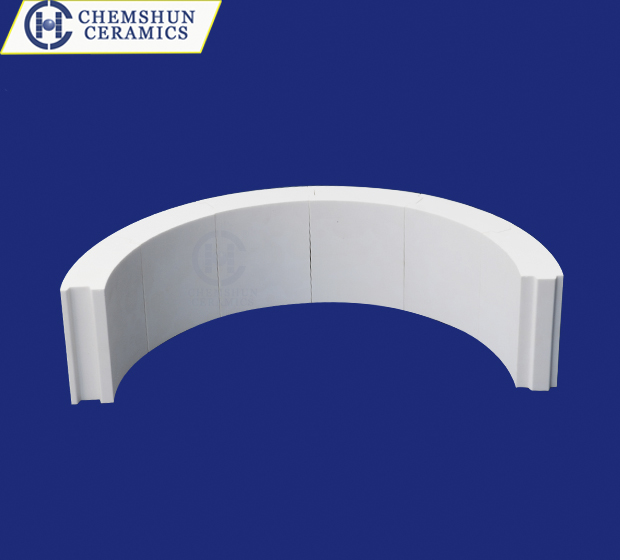

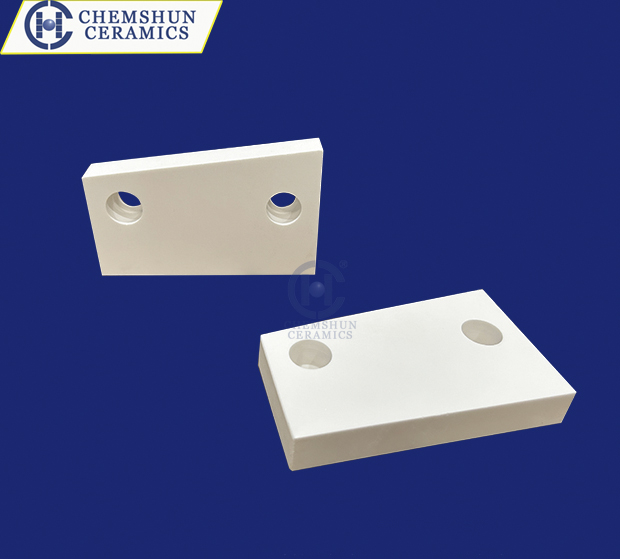

Depending on the type of equipment you need protection for, you may benefit from liners of various shapes. That is why Chemshun Ceramics offers its wear-resistant ceramic products as cylinders, trapezoid bricks, blocks, and sheets in a plethora of standard size options. Also, you can find tiles with excellent weldability characteristics for custom applications.

Regardless of the shape, our alumina coatings are designed to deliver:

· Enhanced resistance. Whether your parts are exposed to mechanical, chemical, or both impact types, our products will ensure that their effects are reduced to a bare minimum.

· Excellent thermal stability. With durable structures and great hardness features, these alumina coatings can withstand not only heavy-duty usage but also high temperatures.

· Effective wear protection. Abrasion-resistant ceramics are matchless in filling vulnerable spots on metal parts , making sure even thin surface layers are not severely damaged .

· High cost-efficiency. Investing in top-grade coatings can save you a great deal of money on unplanned maintenance and reduce the risk of unexpected downtime.

We are here to accept all orders, large or small, and take care of timely delivery. You can also leave on-site product installation to our specialists who will make sure your abrasion-resistant ceramic-lined pipe, chute, or whatever is adequately filled to start the operation.

For further inquiries or OEM/ODM project details, please contact us.

??

Standard industrial wear abrasion resistance ceramic liners

1. From the chemical data, we have the 92% Al2O3 wear resistant ceramics and 95% Al2O3 wear resistant ceramic.

2. From the shapes including: Alumina ceramic plain tiles, Alumina welding ceramic plate, Trapezoid taper ceramic bricks, arc tiles, Ceramic cylinders, Ceramic rods, Alumina blocks and Alumina mosaic ceramics.

3. Customer can choose the proper products according to the detailed application.

Normal Size (Unit:mm) | |||

Type | Length | Width | Thickness |

Plain Tile | 150 | 100 | 6-50 |

Plain Tile | 150 | 50 | 6-25 |

Plain Tile | 100 | 100 | 6-50 |

Plain Tile | 100 | 75 | 6-25 |

Weldable Tile | 150 | 100 | 13-50 |

Weldable Tile | 100 | 100 | 13-50 |

Weldable Tile | 100 | 75 | 13-30 |

Pipe Tile | 152 | 53/49 | 25 |

Pipe Tile | 150 | 33/28 | 13 |

Pipe Tile | 150 | 50/46 | 25 |

Mosaic Tile | 10 | 10 | 2-10 |

Mosaic Tile | 15 | 15 | 2-10 |

Mosaic Tile | 17.5 | 17.5 | 3-15 |

Mosaic Tile | 20 | 20 | 2-13 |

Mosaic Tile | 25 | 25 | 2-10 |

Mosaic Tile | 33 | 33 | 2-25 |

Mosaic Tile | 50 | 25 | 6-25 |

Mosaic Tile | 50 | 50 | 2-25 |

Type | Dia |

| Height |

Cylinder | 20 |

| 20 |

Cylinder | 21 |

| 21 |

Cylinder | 31 |

| 31 |

Cylinder(Half) | 21 |

| 21 |

Cyliner(Half) | 31 |

| 31 |

Mic Structure of 92% Alumina Ceramics

The Pictures of finished alumina ceramics products taken by electron microscope. You can see lower holes and gaps from the pictures, it is better raw material, Chemshun tests and controls every batch of raw material to offering better property wear resistant ceramics to our customer.

-

Weldable alumina tile

Weldable alumina tile -

Ceramic Tile Liner

Ceramic Tile Liner -

Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner -

Ceramic Liner With Salient Point

Ceramic Liner With Salient Point -

Alumina Cylinder

Alumina Cylinder -

95% Alumina Engineering Ceramics

-

Alumina Ceramic Block

Alumina Ceramic Block -

Square Ceramic Tile

Square Ceramic Tile -

Technical Ceramics

Technical Ceramics -

Ceramic Lining Tile Sheet

Ceramic Lining Tile Sheet -

Alumina Wear Pipe Tile Liner with Interlocking

Alumina Wear Pipe Tile Liner with Interlocking -

Abrasion Resistant Cutting Ceramic Tile Liner

Abrasion Resistant Cutting Ceramic Tile Liner

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China